-

-

-

Xiongan New Area, Hebei, China

Stainless Steel Filter Mesh

Sintered Multi Layer Wire Mesh for Industrial Filtration Systems

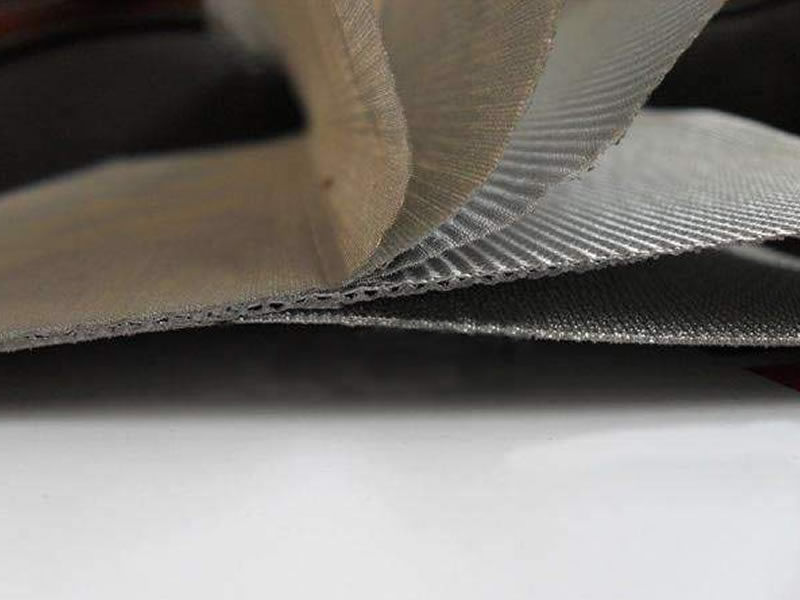

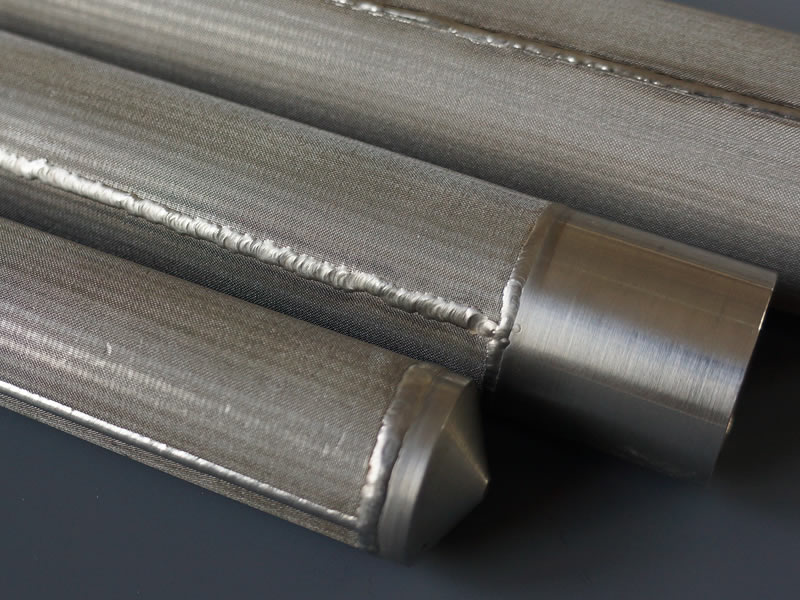

Sintered Multi-Layer Wire Mesh is a metal filter material made by stacking stainless steel wire mesh layers and bonding them through high-temperature sintering in a vacuum furnace. The sintering process forms a strong porous laminate with stable pore size and flow rate. Common designs use five or seven layers including protective, diffusion, and fine filtration mesh. Materials include SS316L, SS304, and Duplex 2205. Thickness ranges from 1 mm to 3.5 mm with filtration ratings from 1 µm to 200 µm. The mesh supports uniform flow, high dirt capacity, and easy backwashing. It is used for high-pressure and high-temperature filtration in petrochemical, pharmaceutical, polymer, and gas processing systems. The material keeps rigidity, resists deformation, and provides consistent filtration under operating load.

Specifications

- Material: SS316L, SS304, Duplex 2205

- Thickness: 1.0 mm – 3.5 mm

- Filtration Rating: 1 µm – 200 µm

- Properties:

Stable pore size

Mechanical strength under load

Corrosion and temperature resistance

Supports backwashing - Applications: Petrochemical filtration, pharmaceutical systems, polymer melt filtration, gas separation and purification

Pictures for examples

Sintered Multi Layer Wire Mesh For Filtration

Sintered Metal Wire Mesh For Process Filtration

Stainless Steel Sintered Wire Mesh